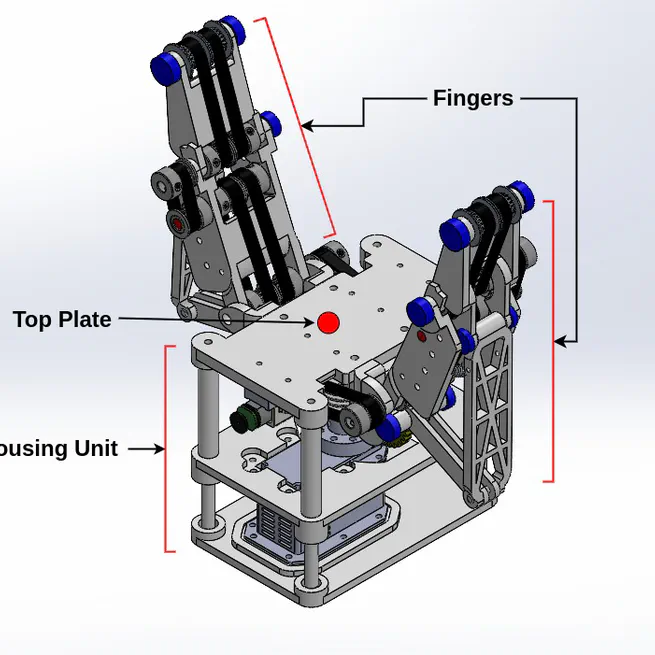

Intelligent Grasping and In-Hand Manipulation (Final Year Project) Overview: The intelligent grasping project successfully addressed grasping location detection for non-standard objects, but further development was required in terms of post-grasp dexterity. The ability for a robot to manipulate objects post-grasp remains a critical challenge in robotic manipulation, a challenge I chose to address for my final year project on In-Hand Manipulation. Design and Implementation: Mechanical Design: We identified that traditional thread-driven underactuated grippers often lacked sufficient grasping force. To resolve this, we developed a four-bar linkage mechanism with an active belt system, enabling enhanced manipulation capabilities. The active belt system was innovatively driven by a single N20 micro motor, controlling both links in a finger, compared to conventional designs that use separate motors for each link. Actuation and Control: The active belt mechanism, powered by a spur and worm drive, was coupled with a Dynamixel servo motor to centralize control over the gripper’s finger movements. This allowed for precise in-hand manipulation of objects with varying geometries. The mechanically underactuated design with an active surface enabled both secure grasping and intricate manipulation. Key Innovations: Single-motor-driven active belt system for compact and efficient control of finger movement. Spur and worm mechanism for centralized control over multiple finger segments, reducing mechanical complexity while maintaining high dexterity. Integration of a Dynamixel servo for robust control, allowing for smooth and adaptive manipulation of different objects.

Feb 28, 2024

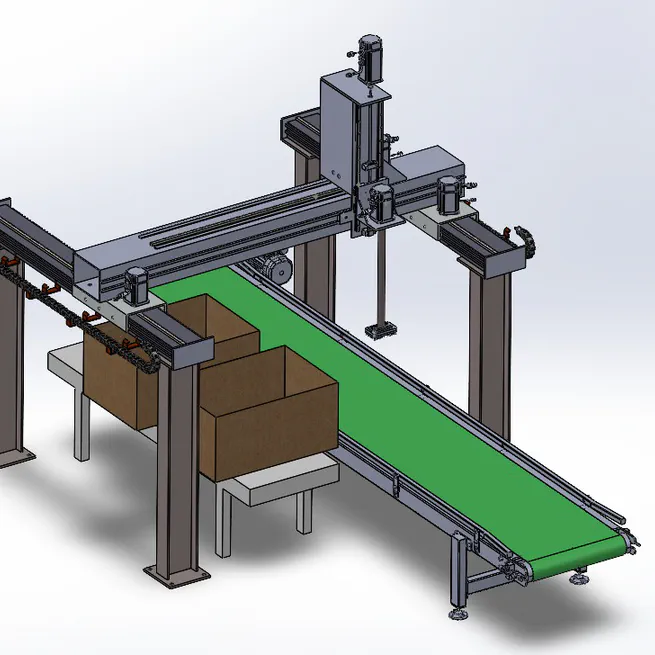

Delta Electronics Automation Contest (March 2021) Project: Gantry-Based System for Efficient Segregation and Packaging In March 2021,i was part of a team participated in the Delta Electronics Automation Contest, where we submitted a proposal to address the challenge of efficiently segregating and packaging different-sized boxes in a warehouse setting. Project Overview Our solution proposed a gantry-based system designed to perform pick, place, and sorting operations for various box sizes. The system aimed to maximize volume occupancy inside a larger container using a vision system to determine the size and orientation of the boxes. Development Process Design and Research: We refined our gantry robot design through consultations with professors and industry experts. Manufacturing: After finalizing the design, we employed different manufacturing techniques to produce the parts. Despite the challenges posed by the pandemic, we successfully fabricated and assembled the robot. Achievements Despite the obstacles, we secured the Second Category Prize and ranked in the Top 40 globally. Project Proposal: Click here to view our work Working Video: Check out the video here

Jul 23, 2021